发表于:2018/11/22 17:01:51

#0楼

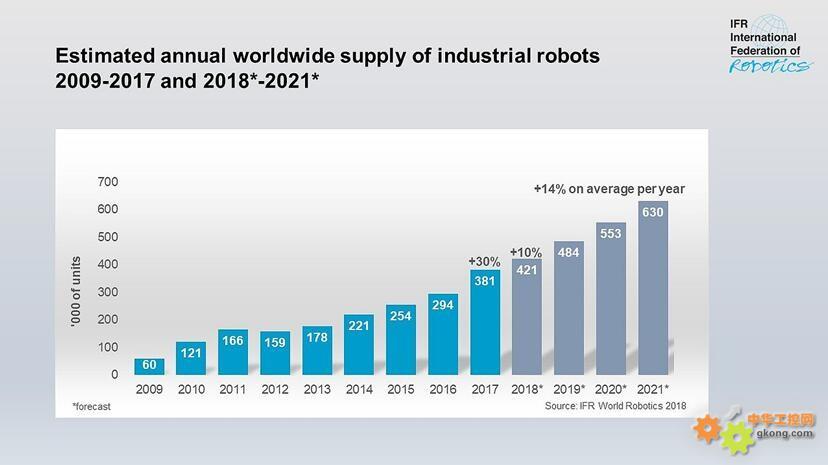

Global industrial robot sales doubled over the past five years

过去五年全球工业机器人销量翻倍

The IFR’s new World Robotics Report shows that a new record high of 381,000 units were shipped globally in 2017 – an increase of 30 percent compared to the previous year. This means that the annual sales volume of industrial robots increased by 114 percent over the last five years (2013-2017). The sales value increased by 21 percent compared to 2016 to a new peak of US$16.2 billion in 2017.

国际机器人联合会(IFR)最新发布的《世界机器人报告》显示,2017年全球机器人出货量创下新高,达到38.1万台,同比增30%。这意味着过去五年(2013-2017年)工业机器人年销量增长了114%。与2016年相比,2017年销售额增长21%,达到162亿美元,亦创下历史新高。

“Industrial robots are a crucial part of the progress of manufacturing industry,” says Junji Tsuda, President of the International Federation of Robotics. “Robots evolve with many cutting-edge technologies. They are vision recognition, skill learning, failure prediction utilizing AI, new concept of man-machine-collaboration plus easy programming and so on. They will help improve productivity of manufacturing and expand the field of robot application. The IFR outlook shows that in 2021 the annual number of robots supplied to factories around the world will reach about 630,000 units.”

“工业机器人是推动制造业进步的关键因素,”IFR主席Junji Tsuda说。“机器人随着许多尖端技术的发展而进化,包括视觉识别、技能学习、应用人工智能的故障预测、人机协作新概念以及简单编程等等。它们将有助于提高生产效率,扩大机器人应用领域。IFR预计到2021年,全球每年为工厂提供的机器人数量将达到63万台。”

Top five markets in the world

全球五大市场

There are five major markets representing 73 percent of the total sales volume in 2017: China, Japan, South Korea, the United States and Germany.

2017年,中国、日本、韩国、美国和德国这五大机器人市场占总销量的73%。

China has significantly expanded its leading position with the strongest demand and a market share of 36 percent of the total supply in 2017. With sales of about 138,000 industrial robots (2016-2017: +59 percent) China′s sales volume was higher than the total sales volume of Europe and the Americas combined (112,400 units). Foreign robot suppliers increased their sales by 72 percent to 103,200 units, including robots produced locally by international robot suppliers in China. This is the first time that foreign robot suppliers have a higher growth rate than the local manufacturers. The market share of the Chinese robot suppliers decreased from 31 percent in 2016 to 25 percent in 2017.

2017年,中国以最强劲的需求和占总供应量36%的市场份额显著扩大其领先地位。工业机器人在中国的销量大约为13.8万台(2016-2017年:+ 59%),高于欧洲和美洲的总销量(11.24万台)。外国机器人供应商的销售额增长了72%,达到10.32万台,其中包括中国国际机器人供应商在当地生产的机器人。这是外国机器人供应商第一次比本地制造商有更高的增长率。中国机器人供应商的市场份额从2016年的31%下降到2017年的25%。

Japan′s manufacturers delivered 56 percent of the global supply in 2017. This makes Japan the world′s number one industrial robot manufacturer. The export rate increased by 45 percent (2016-2017). North America, China, the Republic of Korea, and Europe were target export destinations. Robot sales in Japan increased by 18 percent to 45,566 units, representing the second highest value ever witnessed for this country. A higher value was only recorded in the year 2000 with 46,986 units.

2017年,日本制造商出货量占全球总供应量的56%。日本因此跻身世界最大工业机器人制造国。出口率增长45%(2016-2017年)。北美、中国、韩国和欧洲是主要出口目的地。机器人在日本的销量增长了18 %,达到45,566台,是该国有史以来第二高的销量。最高销量出现在2000年,达46,986台。

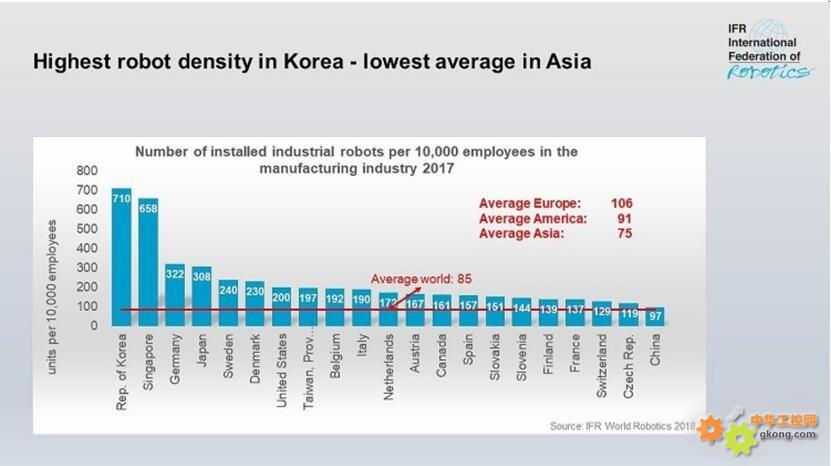

The manufacturing industry of the Republic of Korea has by far the highest robot density in the world – more than 8 times the global average amount. But in 2017, robot supplies decreased by 4 percent to 39,732 units. The main driver of this development was the electrical/electronics industry that reduced robot installations by 18 percent in 2017. The year before, industrial robot installations peaked at 41,373 units.

韩国制造业拥有世界上最高的机器人密度——是全球平均数量的8倍多。但是在2017年,机器人供应量减少了4 %,为39,732台,主要是受电气/电子行业拖累,该行业在2017年减少了18 %的机器人安装量。2016年,韩国工业机器人安装量达41,373台。

Robot installations in the United States continued to increase to a new peak in 2017 – for the seventh year in a row - and reached 33,192 units. This is 6 percent higher than in 2016. Since 2010, the driver of the growth in all manufacturing industries in the U.S. has been the ongoing trend to automate production in order to strengthen the U.S. industries in both domestic and global markets.

2017年,美国市场的机器人安装量连续第七年创新高——达到33,192台。这比2016年高出6 %。自2010年以来,美国所有制造业增长的驱动力一直是自动化生产趋势,以加强美国在国内和全球市场的产业。

Germany is the fifth largest robot market in the world and number one in Europe. In 2017, the number of robots sold increased by 7 percent to 21,404 units - a new all-time record - compared to 2016 (20,074 units). Between 2014 and 2016, annual sales of industrial robots stagnated at around 20,000 units.

德国是世界第五大机器人市场,也是欧洲第一大机器人市场。与2016年(20,074台)相比,2017年售出的机器人数量增长了7 %,达到21,404台,创下历史新高。2014年至2016年间,工业机器人的年销售量停滞在2万台左右。

Robot use by industry worldwide

全球机器人应用行业

The automotive industry remains the largest adopter of robots globally with a share of 33 percent of the total supply in 2017 - sales increased by 22 percent. The manufacturing of passenger cars has become increasingly complex over the past ten years: a substantial proportion of the production processes nowadays require automation solutions using robots. Manufacturers of hybrid and electric cars are experiencing stronger demand for a wider variety of car models just like the traditional car manufacturers. Furthermore, the challenge of meeting 2030 climate targets will finally require a larger proportion of new cars to be low- and zero-emission vehicles.

汽车行业仍然是全球最大的机器人应用行业,占2017年总供应量的33%,销售额增长了22%。 在过去的十年中,乘用车的制造变得越来越复杂:如今很大一部分生产过程需要使用机器人的自动化解决方案。与传统汽车制造商一样,混合动力汽车和电动汽车制造商对更多种车型的需求也越来越大。此外,实现2030年气候目标的挑战最终将需要更大比例的新车是低排放和零排放车辆。

In the future, automotive manufacturers will also invest in collaborative applications for final assembly and finishing tasks. Second tier automotive part suppliers, a large number of which are SMEs, are slower to automate fully but we can expect this to change as robots become smaller, more adaptable, easier to program, and less capital-intensive.

未来,汽车制造商也将投资于最终装配和精加工任务的协同应用。对于大部分是中小企业的二级汽车零部件供应商而言,实现完全自动化还为时尚早,但随着机器人变得更小,适应性更强,更容易编程,资本密集程度更低,我们可以预期这种情况会发生变化。

The electrical/electronics industry has been catching up with the auto industry: Sales increased by 33 percent to a new peak of 121,300 units - accounting for a share of 32 percent of the total supply in 2017. The rising demand for electronic products and the increasing need for batteries, chips, and displays were driving factors for the boost in sales. The need to automate production increases demand: robots can handle very small parts at high speeds, with very high degrees of precision, enabling electronics manufacturers to ensure quality whilst optimising production costs. The expanding range of smart end-effectors and vision technologies extends the range of tasks that robots can perform in the manufacture of electronic products.

电气/电子行业一直在追赶汽车行业:销量增长了33%,达到121,300台的新高峰——占2017年总供应量的32%。对电子产品日益增长的需求以及对电池、芯片和显示器的日益增长的需求是销售增长的驱动因素。自动化生产的需求增加了需求:机器人可以高速、高精度地处理非常小的零件,使电子制造商能够确保质量,同时优化生产成本。智能终端执行器和视觉技术的范围不断扩大,扩大了机器人在电子产品制造中可以执行的任务范围。

The metal industry (including industrial machinery, metal products and basic metals industries) is on an upswing. Share of total supply reached 10 percent with an exceptional sales growth of 55 percent in 2017. Analysts predict an overall growth in demand in 2018 for metals, with ongoing high demand for the cobalt and lithium used in electric car batteries. Large metal and metal product companies are implementing Industry 4.0 automation strategies, including robotics, to reap the benefits of economies of scale and to be able to respond quickly to changes in demand.

金属工业(包括工业机械、金属产品和基本金属工业)正在上升。2017年总供应量的份额达到10%,销售额增长了55%。分析师预测,2018年对金属需求总体增长,对电动汽车电池中使用的钴和锂的需求持续增长。大型金属和金属产品公司正在实施工业4.0自动化战略,包括机器人技术,以获得规模经济效益,并能够快速响应需求变化。

Automation degree by robot density

机器人密度的自动化程度

85 robot units per 10,000 employees is the new average of global robot density in the manufacturing industries (2016: 74 units). By regions, the average robot density in Europe is 106 units, in the Americas 91, and in Asia 75 units.

每万名员工中有85台机器人是制造业中全球机器人密度的新平均值(2016年:74台)。按地区划分,欧洲平均机器人密度为106台,美洲为91台,亚洲为75台。

过去五年全球工业机器人销量翻倍

The IFR’s new World Robotics Report shows that a new record high of 381,000 units were shipped globally in 2017 – an increase of 30 percent compared to the previous year. This means that the annual sales volume of industrial robots increased by 114 percent over the last five years (2013-2017). The sales value increased by 21 percent compared to 2016 to a new peak of US$16.2 billion in 2017.

国际机器人联合会(IFR)最新发布的《世界机器人报告》显示,2017年全球机器人出货量创下新高,达到38.1万台,同比增30%。这意味着过去五年(2013-2017年)工业机器人年销量增长了114%。与2016年相比,2017年销售额增长21%,达到162亿美元,亦创下历史新高。

“Industrial robots are a crucial part of the progress of manufacturing industry,” says Junji Tsuda, President of the International Federation of Robotics. “Robots evolve with many cutting-edge technologies. They are vision recognition, skill learning, failure prediction utilizing AI, new concept of man-machine-collaboration plus easy programming and so on. They will help improve productivity of manufacturing and expand the field of robot application. The IFR outlook shows that in 2021 the annual number of robots supplied to factories around the world will reach about 630,000 units.”

“工业机器人是推动制造业进步的关键因素,”IFR主席Junji Tsuda说。“机器人随着许多尖端技术的发展而进化,包括视觉识别、技能学习、应用人工智能的故障预测、人机协作新概念以及简单编程等等。它们将有助于提高生产效率,扩大机器人应用领域。IFR预计到2021年,全球每年为工厂提供的机器人数量将达到63万台。”

Top five markets in the world

全球五大市场

There are five major markets representing 73 percent of the total sales volume in 2017: China, Japan, South Korea, the United States and Germany.

2017年,中国、日本、韩国、美国和德国这五大机器人市场占总销量的73%。

China has significantly expanded its leading position with the strongest demand and a market share of 36 percent of the total supply in 2017. With sales of about 138,000 industrial robots (2016-2017: +59 percent) China′s sales volume was higher than the total sales volume of Europe and the Americas combined (112,400 units). Foreign robot suppliers increased their sales by 72 percent to 103,200 units, including robots produced locally by international robot suppliers in China. This is the first time that foreign robot suppliers have a higher growth rate than the local manufacturers. The market share of the Chinese robot suppliers decreased from 31 percent in 2016 to 25 percent in 2017.

2017年,中国以最强劲的需求和占总供应量36%的市场份额显著扩大其领先地位。工业机器人在中国的销量大约为13.8万台(2016-2017年:+ 59%),高于欧洲和美洲的总销量(11.24万台)。外国机器人供应商的销售额增长了72%,达到10.32万台,其中包括中国国际机器人供应商在当地生产的机器人。这是外国机器人供应商第一次比本地制造商有更高的增长率。中国机器人供应商的市场份额从2016年的31%下降到2017年的25%。

Japan′s manufacturers delivered 56 percent of the global supply in 2017. This makes Japan the world′s number one industrial robot manufacturer. The export rate increased by 45 percent (2016-2017). North America, China, the Republic of Korea, and Europe were target export destinations. Robot sales in Japan increased by 18 percent to 45,566 units, representing the second highest value ever witnessed for this country. A higher value was only recorded in the year 2000 with 46,986 units.

2017年,日本制造商出货量占全球总供应量的56%。日本因此跻身世界最大工业机器人制造国。出口率增长45%(2016-2017年)。北美、中国、韩国和欧洲是主要出口目的地。机器人在日本的销量增长了18 %,达到45,566台,是该国有史以来第二高的销量。最高销量出现在2000年,达46,986台。

The manufacturing industry of the Republic of Korea has by far the highest robot density in the world – more than 8 times the global average amount. But in 2017, robot supplies decreased by 4 percent to 39,732 units. The main driver of this development was the electrical/electronics industry that reduced robot installations by 18 percent in 2017. The year before, industrial robot installations peaked at 41,373 units.

韩国制造业拥有世界上最高的机器人密度——是全球平均数量的8倍多。但是在2017年,机器人供应量减少了4 %,为39,732台,主要是受电气/电子行业拖累,该行业在2017年减少了18 %的机器人安装量。2016年,韩国工业机器人安装量达41,373台。

Robot installations in the United States continued to increase to a new peak in 2017 – for the seventh year in a row - and reached 33,192 units. This is 6 percent higher than in 2016. Since 2010, the driver of the growth in all manufacturing industries in the U.S. has been the ongoing trend to automate production in order to strengthen the U.S. industries in both domestic and global markets.

2017年,美国市场的机器人安装量连续第七年创新高——达到33,192台。这比2016年高出6 %。自2010年以来,美国所有制造业增长的驱动力一直是自动化生产趋势,以加强美国在国内和全球市场的产业。

Germany is the fifth largest robot market in the world and number one in Europe. In 2017, the number of robots sold increased by 7 percent to 21,404 units - a new all-time record - compared to 2016 (20,074 units). Between 2014 and 2016, annual sales of industrial robots stagnated at around 20,000 units.

德国是世界第五大机器人市场,也是欧洲第一大机器人市场。与2016年(20,074台)相比,2017年售出的机器人数量增长了7 %,达到21,404台,创下历史新高。2014年至2016年间,工业机器人的年销售量停滞在2万台左右。

Robot use by industry worldwide

全球机器人应用行业

The automotive industry remains the largest adopter of robots globally with a share of 33 percent of the total supply in 2017 - sales increased by 22 percent. The manufacturing of passenger cars has become increasingly complex over the past ten years: a substantial proportion of the production processes nowadays require automation solutions using robots. Manufacturers of hybrid and electric cars are experiencing stronger demand for a wider variety of car models just like the traditional car manufacturers. Furthermore, the challenge of meeting 2030 climate targets will finally require a larger proportion of new cars to be low- and zero-emission vehicles.

汽车行业仍然是全球最大的机器人应用行业,占2017年总供应量的33%,销售额增长了22%。 在过去的十年中,乘用车的制造变得越来越复杂:如今很大一部分生产过程需要使用机器人的自动化解决方案。与传统汽车制造商一样,混合动力汽车和电动汽车制造商对更多种车型的需求也越来越大。此外,实现2030年气候目标的挑战最终将需要更大比例的新车是低排放和零排放车辆。

In the future, automotive manufacturers will also invest in collaborative applications for final assembly and finishing tasks. Second tier automotive part suppliers, a large number of which are SMEs, are slower to automate fully but we can expect this to change as robots become smaller, more adaptable, easier to program, and less capital-intensive.

未来,汽车制造商也将投资于最终装配和精加工任务的协同应用。对于大部分是中小企业的二级汽车零部件供应商而言,实现完全自动化还为时尚早,但随着机器人变得更小,适应性更强,更容易编程,资本密集程度更低,我们可以预期这种情况会发生变化。

The electrical/electronics industry has been catching up with the auto industry: Sales increased by 33 percent to a new peak of 121,300 units - accounting for a share of 32 percent of the total supply in 2017. The rising demand for electronic products and the increasing need for batteries, chips, and displays were driving factors for the boost in sales. The need to automate production increases demand: robots can handle very small parts at high speeds, with very high degrees of precision, enabling electronics manufacturers to ensure quality whilst optimising production costs. The expanding range of smart end-effectors and vision technologies extends the range of tasks that robots can perform in the manufacture of electronic products.

电气/电子行业一直在追赶汽车行业:销量增长了33%,达到121,300台的新高峰——占2017年总供应量的32%。对电子产品日益增长的需求以及对电池、芯片和显示器的日益增长的需求是销售增长的驱动因素。自动化生产的需求增加了需求:机器人可以高速、高精度地处理非常小的零件,使电子制造商能够确保质量,同时优化生产成本。智能终端执行器和视觉技术的范围不断扩大,扩大了机器人在电子产品制造中可以执行的任务范围。

The metal industry (including industrial machinery, metal products and basic metals industries) is on an upswing. Share of total supply reached 10 percent with an exceptional sales growth of 55 percent in 2017. Analysts predict an overall growth in demand in 2018 for metals, with ongoing high demand for the cobalt and lithium used in electric car batteries. Large metal and metal product companies are implementing Industry 4.0 automation strategies, including robotics, to reap the benefits of economies of scale and to be able to respond quickly to changes in demand.

金属工业(包括工业机械、金属产品和基本金属工业)正在上升。2017年总供应量的份额达到10%,销售额增长了55%。分析师预测,2018年对金属需求总体增长,对电动汽车电池中使用的钴和锂的需求持续增长。大型金属和金属产品公司正在实施工业4.0自动化战略,包括机器人技术,以获得规模经济效益,并能够快速响应需求变化。

Automation degree by robot density

机器人密度的自动化程度

85 robot units per 10,000 employees is the new average of global robot density in the manufacturing industries (2016: 74 units). By regions, the average robot density in Europe is 106 units, in the Americas 91, and in Asia 75 units.

每万名员工中有85台机器人是制造业中全球机器人密度的新平均值(2016年:74台)。按地区划分,欧洲平均机器人密度为106台,美洲为91台,亚洲为75台。